Apa itu langit-langit sel terbuka?

2024-11-01 11:31

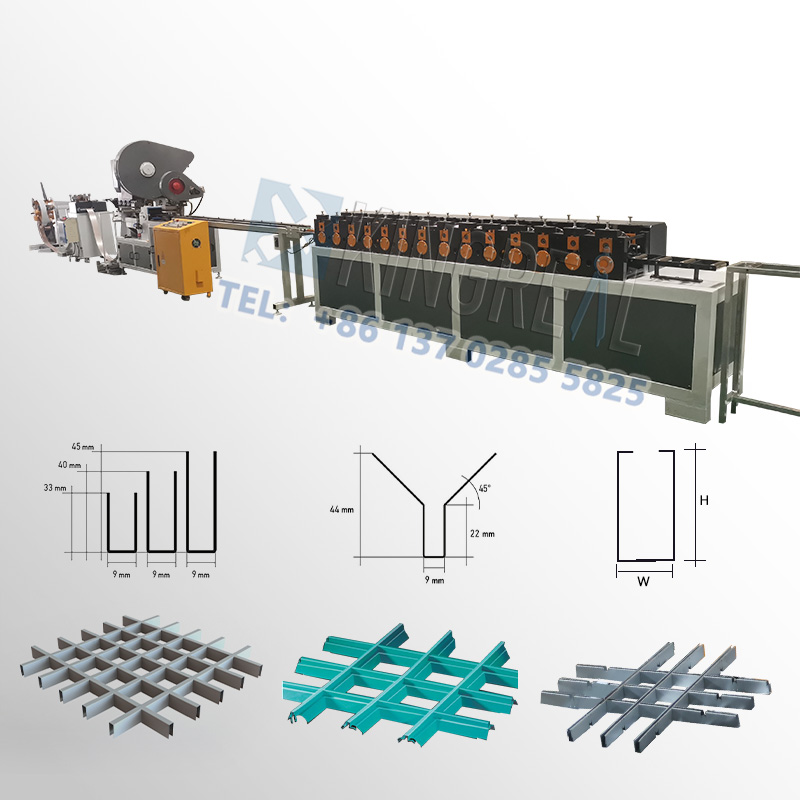

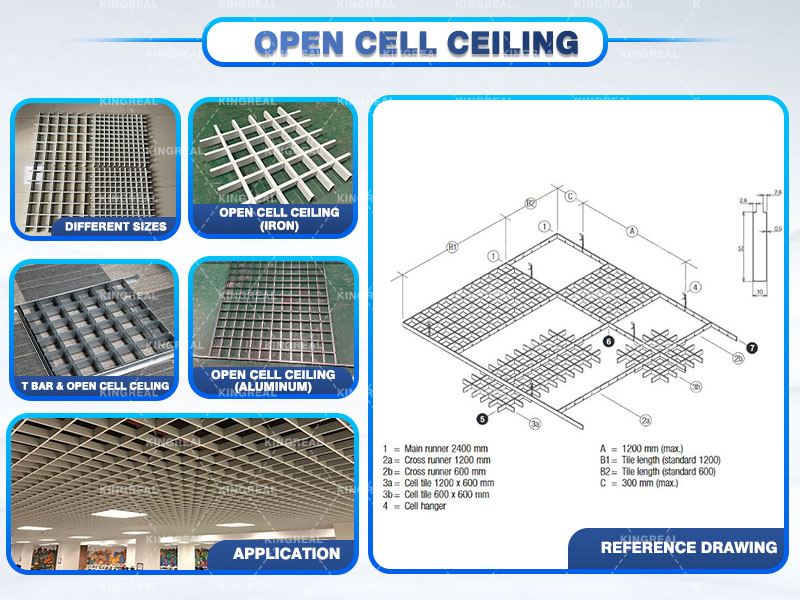

Ubin langit-langit sel terbuka diproduksi olehmesin roll forming langit-langit sel terbuka melalui proses seperti penggulungan, perataan, pelubangan, penggulungan, dan pemotongan bahan baku logam.

Dalam beberapa tahun terakhir, plafon sel terbuka telah muncul sebagai salah satu material plafon yang populer. Dengan garis-garisnya yang bersih, lurus, dan pelapisan yang jelas, plafon ini mencerminkan gaya minimalis dan modern. Plafon ini mudah dipasang dan dibongkar, sehingga menjadi produk yang disukai di pasar dekorasi.

Artikel ini akan membantu Anda mengetahui lebih banyak tentang langit-langit sel terbuka.

Video tentang Mesin Plafon Sel Terbuka

Karakteristik Plafon Sel Terbuka

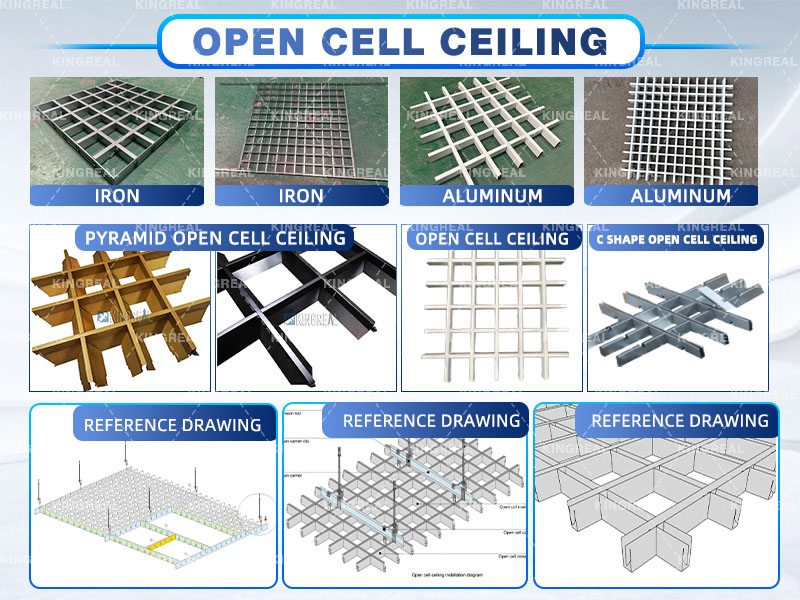

Plafon gantung sel terbuka aluminium melalui bentuk khusus badan unit dan kombinasi badan unit, sehingga atap bagian dalam bangunan tertutup dan transparan, kisi-kisi garis vertikal, horizontal dan miring, dan pertimbangan terpadu dengan pengaturan pencahayaan, meningkatkan efek artistik keseluruhan dari permukaan dekoratif, ia memiliki karakteristik berikut:

Desain Ruang Terbuka

Memfasilitasi tata letak dan pengaturan ventilasi dan penyiram kebakaran tanpa mempengaruhi efek visual keseluruhan.

Paduan Aluminium Berkualitas Tinggi

Dapat dipasangkan dengan sistem bingkai terbuka untuk dekorasi.

Warna Konsisten

Warna seragam yang tidak berubah hingga 10 tahun saat digunakan di dalam ruangan.

Instalasi dan Perawatan Mudah

Mudah dan nyaman untuk dipasang dan dibongkar, dengan sambungan yang aman. Setiap sel dapat dipasang kembali berulang kali, yang memudahkan perawatan.

Kompatibilitas Pencahayaan Serbaguna

Dapat dikombinasikan dengan berbagai jenis pencahayaan, seperti lampu downlight dan lampu neon, serta dapat dirakit sesuai kebutuhan aktual untuk hasil optimal.

Tinggi Konsisten dan Penampilan Rapi

Garis-garis yang selaras dan jelas memberikan tampilan yang rapi dan luas, menghindari tampilan yang kusam dan kaku.

Proses Konstruksi

(1) Tata Letak Situs

Berdasarkan rencana plafon, tandai garis tata letak memanjang dan melintang dari bahan-bahan komponen, garis kerangka area kompleks, dan garis ketinggian plafon. Selain itu, tentukan dan tandai titik-titik suspensi untuk plafon.

(2) Mengamankan Plafon

Perbaiki sambungan langit-langit menggunakan baut ekspansi logam atau paku sesuai kebutuhan desain, atau kencangkan langsung dengan batang baja, kawat galvanis, dan gantungan besi datar.

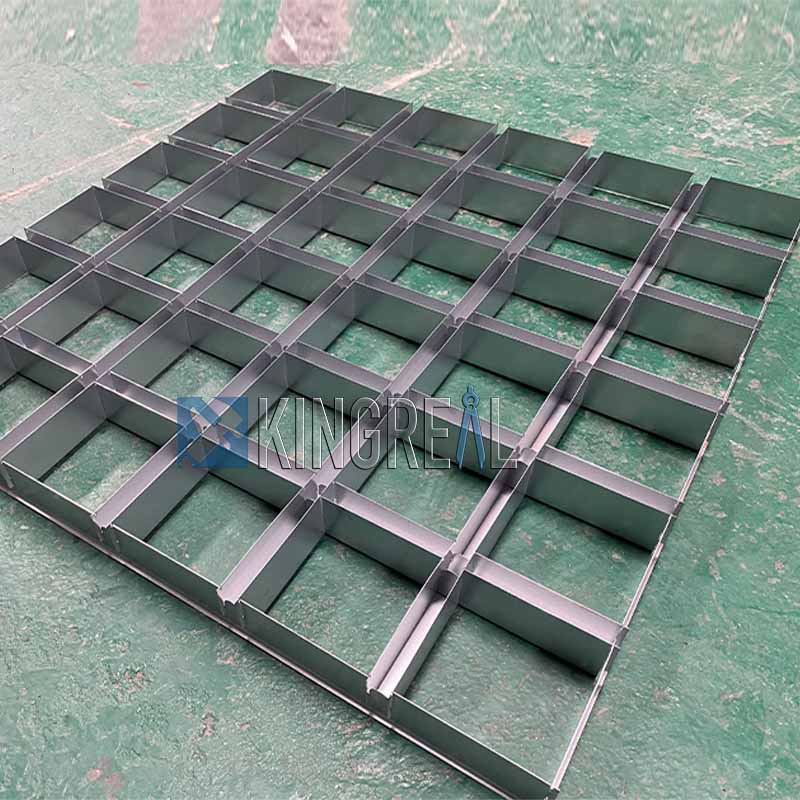

(3) Perakitan dan Pemasangan Plafon Palsu Sel Terbuka

Pasang plafon gantung sel terbuka secara lokal, gabungkan unit dan elemen tunggal untuk membentuk pola ritmis pada plafon. Pasang di tanah jika memungkinkan sebelum menggantung sesuai persyaratan desain. Pastikan sambungan aman antara komponen menggunakan paku, perekat, pasak, dan tulangan dengan potongan logam.

(4) Menggantung Langit-langit Sel Terbuka

Ratakan dan kencangkan langit-langit sel terbuka. Setelah memposisikan langit-langit sel terbuka aluminium, kencangkan batang suspensi untuk bagian yang menonjol dan kendurkan untuk bagian yang tersembunyi. Perkuat langit-langit sel terbuka sesuai dengan itu. Untuk kisi-kisi dengan tata letak yang rapat dan bentang yang besar, bagian tengah langit-langit harus memiliki sedikit lengkungan.

Pertimbangan

Jenis-jenis Plafon Sel Terbuka Aluminium

Plafon sel terbuka aluminium dapat dibagi menjadi tipe beralur dan datar. Mengingat luas permukaannya yang besar, pastikan keselarasan yang tepat antara kisi logam dan papan wol mineral, serta antara plafon dan dinding atau kolom. Gunakan sumbu yang relevan untuk menandai permukaan dinding dan kolom dan sejajarkan plesteran sesuai dengan itu untuk memastikan dinding sejajar dengan sumbu dan permukaan yang berdekatan tegak lurus.

Lengkungan dan Ketinggian

Tinggi lengkungan dapat sekitar 1/200 dari jarak kolom (misalnya, 8 meter).

Lubang Inspeksi

Karena berbagai pipa di langit-langit kisi memiliki katup penyetelan, tinggalkan lubang pemeriksaan di lokasi yang sesuai. Pastikan kepala sprinkler kebakaran tidak tumpang tindih dengan batang kisi dan sejajar di kedua arah. Buat lengkungan besar lebih dari 90° di bagian atas riser sprinkler untuk menyempurnakan posisi kepala sprinkler.

Lubang Inspeksi Peralatan

Untuk pipa dengan katup penyetelan, tinggalkan lubang pemeriksaan pada posisi yang sesuai. Karena lubang ini mungkin tidak sejajar secara vertikal dan horizontal, potong lubang terlebih dahulu, lalu tambahkan aluminium siku di sekeliling lubang (dicat dengan warna yang sama dengan kisi). Terakhir, setel dan tempatkan batang kisi yang dipotong pada aluminium siku.

Perawatan Node antara Langit-langit dan Dinding/Kolom

Gunakan aluminium siku L20mm*20mm untuk sambungan dengan kolom persegi agar sesuai dengan rangka langit-langit papan wol mineral. Untuk kolom melingkar, gunakan cincin pipa baja tahan karat φ35 untuk penyegelan tepi.

KINGREAL CEILING MACHINERY adalah produsen profesional dengan pengalaman lebih dari 20 tahun dalam industri pembuatan plafon logam. Jika Anda tertarik dengan topik lainnya, silakan terus ikutiMESIN LANGIT-LANGIT KINGREAL!

Dapatkan harga terbaru? Kami akan merespons sesegera mungkin (dalam 12 jam)