Mesin Perata Lembaran Logam

Mesin perata lembaran logam KINGREAL CEILING MACHINERY merupakan peralatan perata presisi tinggi yang dapat meratakan berbagai jenis material logam seperti pelat logam, kasa logam, komponen logam, dan produk logam berbentuk lainnya.

- KINGREAL CEILING MACHINERY

Detail

- Mesin perata lembaran logam empat-tinggi: Karena jumlah rol sedikit dan titik-titik tekanan terkonsentrasi, lekukan atau perataan yang tidak lengkap dapat terjadi saat memproses pelat tebal.

Bagaimana cara memilih perata lembaran logam?

(1) Ketebalan lembaran dan jenis bahan

Sangat penting untuk memilih mesin perata pelat baja yang sesuai dengan ketebalan lembaran dan jenis material yang ingin Anda proses. Pastikan mesin perata lembaran logam tersebut dapat memenuhi kebutuhan spesifik Anda untuk mencapai hasil perataan terbaik.

(2) Kapasitas pemerataan Pilih mesin perata pelat baja dengan kapasitas perataan yang memadai untuk menyesuaikan volume produksi dan kebutuhan pemrosesan Anda. Kapasitas perataan yang tidak memadai dapat mengakibatkan hasil perataan yang buruk, yang akan memengaruhi pemrosesan selanjutnya. |  |

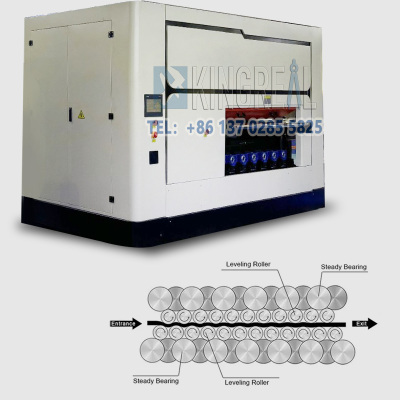

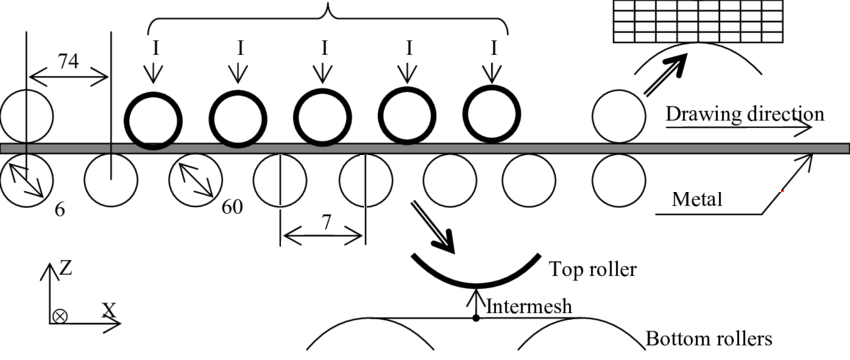

(3) Jumlah rol

Jumlah rol secara langsung memengaruhi kinerja perata lembaran logam. Lebih banyak rol biasanya berarti distribusi tekanan yang lebih merata dan kualitas perataan yang lebih tinggi, sehingga jumlah dan konfigurasi rol perlu dipertimbangkan saat memilih.

(4) Tingkat otomatisasi

Mesin perata lembaran logam tersedia dalam pilihan manual, semi-otomatis, atau otomatis penuh. Pilih tingkat otomatisasi yang sesuai dengan kebutuhan dan anggaran produksi aktual untuk meningkatkan efisiensi produksi dan kemudahan pengoperasian.

(5) Merek dan layanan

Memilih merek tepercaya biasanya memberi Anda jaminan kualitas dan dukungan layanan purna jual yang lebih tinggi. Pastikan produsen dapat menyediakan dukungan teknis dan layanan pemeliharaan yang tepat waktu untuk mengurangi dampak kegagalan mesin perata pelat baja pada produksi.

Bidang Aplikasi Perata Lembaran Logam

(1) Dirgantara

Terutama digunakan untuk memproses lembaran logam untuk badan pesawat, permukaan sayap, dan komponen penting lainnya. Komponen-komponen ini membutuhkan kerataan dan presisi yang sangat tinggi untuk memastikan kinerja aerodinamis dan kekuatan struktural yang baik selama penerbangan. Mesin perata pelat baja ini dapat secara efektif menghilangkan lengkungan dan deformasi material serta memastikan kualitas pemrosesan komponen.

(2) Industri konstruksi

Banyak digunakan dalam pemrosesan material bangunan logam, seperti balok baja, pelat baja, dan komponen struktur baja. Melalui perataan, material ini dapat mencapai kesesuaian pemasangan dan daya dukung beban yang lebih baik, serta meningkatkan stabilitas dan keamanan struktur bangunan.

(3) Industri

Digunakan untuk produksi dan pemrosesan berbagai suku cadang dan komponen logam. Suku cadang ini dapat digunakan pada peralatan mekanik, sistem transmisi, dan peralatan otomasi industri.

(4) Industri pembuatan kapal

Digunakan untuk memproses lembaran logam untuk lambung kapal dan struktur internal. Material ini harus memiliki kerataan dan kekuatan yang baik agar tahan terhadap tantangan lingkungan laut. Penggunaan perata lembaran logam dapat memastikan kualitas pemrosesan komponen kapal dan meningkatkan kinerja serta keselamatan kapal secara keseluruhan.

(5) Industri otomotif

Terutama digunakan untuk memproses material logam pada bodi mobil, sasis, dan komponen penting lainnya. Komponen ini membutuhkan kerataan dan kekuatan yang tinggi untuk memastikan persyaratan keselamatan dan performa mobil. Perata lembaran logam dapat secara efektif menghilangkan deformasi pelat, memastikan akurasi pencocokan bodi dan sasis mobil, sehingga meningkatkan keamanan dan kenyamanan seluruh kendaraan.

FAQ Tentang Mesin Perata Lembaran Logam

Bagaimana cara kerja mesin perata rol?

Apa prinsip kerja mesin perata lembaran logam?

Apa tujuan dari mesin perata lembaran logam?

Mengapa kita membutuhkan mesin pelurus lembaran?

Apa saja aplikasi mesin pelurus logam?

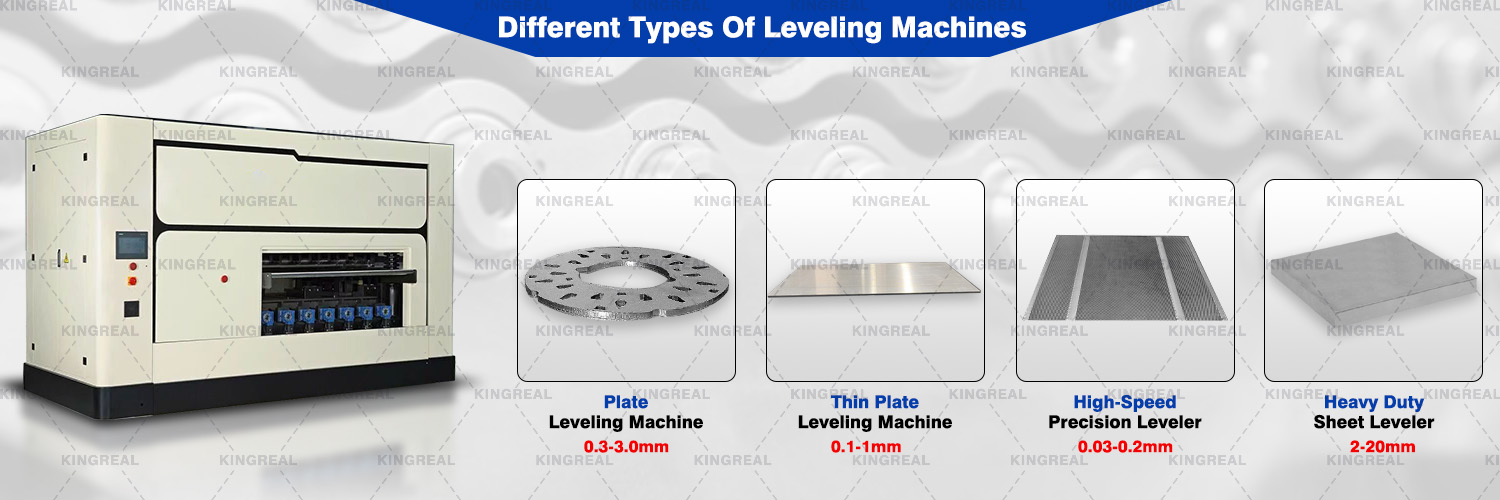

This sheet metal flattening machine can straighten thin materials such as motor stators and rotors with a thickness range of 0.03-0.2mm at speeds up to 60m/min. This is especially important in applications requiring rapid, high-volume production, as this high-efficiency sheet metal flattening machine significantly shortens production cycles and reduces production costs.

Heavy Duty Sheet Leveler

Designed for handling materials with a thickness range of 2-20mm, this sheet metal flattening machine boasts powerful leveling capabilities to meet the needs of various industrial applications. For customers with even thicker material processing requirements, KINGREAL CEILING MACHINERY engineers will design a corresponding sheet metal flattening machine based on the specific project, ensuring the sheet metal flattening machine's performance and stability meet customer requirements.

Sheet Metal Flattener Frequently Asked Questions

What's the difference between four-high and six-high sheet metal flattening machine?

(1) Number of rollers and structure

- Four-high sheet metal flattening machine: It is composed of two upper rollers and two lower rollers, with a relatively simple structure, suitable for basic leveling needs.

- Six-high sheet metal flattening machine: It is composed of three upper rollers and three lower rollers, with additional support rollers. This structural design makes the pressure distribution more uniform and effectively improves the leveling effect.

(2) Leveling ability

- Four-high steel plate flattening machine: It is suitable for processing thinner plates or materials with lower stress requirements, and is suitable for light leveling work.

- Six-high steel plate flattening machine: It has strong leveling ability and can process plates with higher hardness and thicker thickness to meet more stringent production requirements.

(3) Pressure distribution

- Four-high sheet metal flattening machine: Due to the small number of rollers and concentrated pressure points, indentations or incomplete leveling may occur when processing thick plates.

- Six-high sheet metal flattening machine: The design of the support roller makes the pressure more evenly distributed, thereby reducing surface damage, improving the leveling quality, and ensuring the consistency of the processing effect.

How to choose a sheet metal flattener?

(1) Sheet thickness and material type

It is crucial to choose a steel plate flattening machine that is suitable for the sheet thickness and material type you want to process. Make sure the sheet metal flattening machine can meet your specific needs to achieve the best leveling effect.

(2) Leveling capacity

Choose a steel plate flattening machine with sufficient leveling capacity to adapt to your production volume and processing requirements. Insufficient leveling capacity may result in poor leveling results, which will affect subsequent processing.

(3) Number of rollers

The number of rollers directly affects the performance of the sheet metal flattener. More rollers usually mean more uniform pressure distribution and higher leveling quality, so the number and configuration of rollers should be considered when choosing.

(4) Automation level

Sheet metal flatteners can have manual, semi-automatic or fully automatic options. Choose the appropriate automation level according to actual production needs and budget to improve production efficiency and ease of operation.

(5) Brand and service

Choosing a trusted brand usually gives you higher quality assurance and after-sales service support. Make sure the manufacturer can provide timely technical support and maintenance services to reduce the impact of steel plate flattening machine failure on production.

Application Fields Of Sheet Metal Flattener

(1) Aerospace

Mainly used to process metal sheets for aircraft fuselages, wing surfaces and other key components. These components require extremely high flatness and precision to ensure good aerodynamic performance and structural strength during flight. The steel plate flattening machine can effectively eliminate the warping and deformation of the material and ensure the processing quality of the components.

(2) Construction industry

Widely used in the processing of metal building materials, such as steel beams, steel plates and steel structural parts. Through leveling, these materials can achieve better installation fit and load-bearing capacity, and improve the stability and safety of the building structure.

(3) Industry

Used for the production and processing of various metal parts and components. These parts may be used in mechanical equipment, transmission systems and industrial automation equipment.

(4) Shipbuilding industry

Used to process metal sheets for hulls and internal structures. These materials need to have good flatness and strength to withstand the challenges of the marine environment. The application of the sheet metal flattener can ensure the processing quality of ship components and improve the overall performance and safety of the ship.

(5) Automobile industry

Mainly used to process metal materials for car bodies, chassis and other important parts. These parts require high flatness and strength to ensure the safety and performance requirements of the car. The sheet metal flattener can effectively eliminate the deformation of the plate, ensure the matching accuracy of the car body and chassis, and thus improve the safety and comfort of the whole vehicle.

FAQ About Sheet Metal Flattening Machine

Tag produk

Dapatkan harga terbaru? Kami akan merespons sesegera mungkin (dalam 12 jam)